Forging the Future: Precision Magnetics for Factory Automation & Production

Powering the Production Line: Critical Applications

Welding & Plasma Cutting Systems

Our transformers and inductors are foundational to power conversion and voltage regulation in welding and cutting equipment. They stabilize current for consistent arcs and plasma streams, enabling precise, high-efficiency operations.

- Compact, high-efficiency designs reduce energy loss and improve thermal performance

- Inverter-based solutions enhance portability and versatility across welding types

- Thermal optimization extends equipment life and supports continuous operation

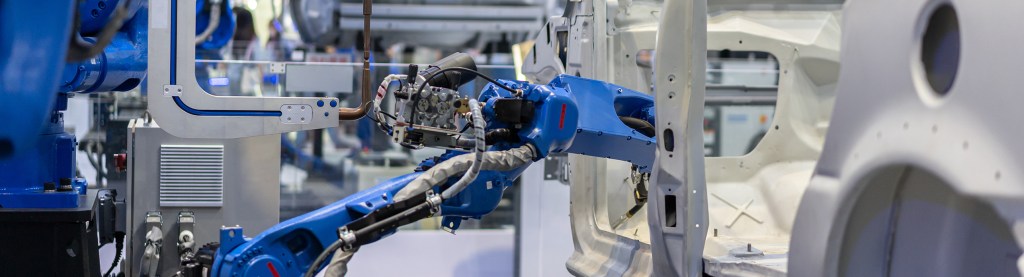

Capital Equipment & General Manufacturing

Standex magnetics support a wide range of industrial systems, including:

- Power conversion for automation and robotics

- Custom solutions for conveying, lifting, tooling, and material handling

- High DC saturation chokes for LED drivers and lighting control

- Magnetic sweepers and safety systems for forklifts and hybrid machinery

- UPS systems for uninterrupted power to industrial computing and control systems

Driving Efficiency & Thermal Performance

Our magnetics are engineered to meet the high power density and thermal demands of industrial manufacturing:

- Low-loss materials (ferrite, high-permeability, high-frequency cores)

- Optimized core structures (e.g., distributed gap ferrite cores) to reduce saturation and losses

- Planar magnetics for compact, high-frequency operation with excellent heat dissipation

- Integrated magnetics that combine multiple functions to save space and improve energy transfer

With advanced thermal management features—including high surface-to-volume ratios and direct heat sink mounting—our components maintain performance under high current loads and continuous operation.

Resilience and Customization for Demanding Environments

Standex ensures components for manufacturing are robust and tailored to specific needs:

Unwavering Reliability & Durability:

Our products are built for high reliability and durability, which is crucial for manufacturing environments characterized by high temperatures, vibrations, and potential contamination. Our magnetics are designed to be less susceptible to mechanical vibration and shock due to their lower profile and robust construction. We ensure long-term durability through encapsulation, robust winding techniques, and the use of high-temperature-rated materials. Standex adheres to stringent UL safety and compliance standards for its components.

Customization and Partnership:

Standex excels in providing custom-engineered components to meet the unique form factor and performance demands of industrial manufacturing. We offer expertise in design-for-manufacturing (DFM) to mitigate fluctuations in component availability and optimize cost-effective assembly strategies. Our capabilities include rapid prototyping, with custom samples available in two weeks or less. Standex’s global manufacturing footprint enables production scaling and ensures supply chain stability, even during disruptions, by coordinating raw material sourcing. Our comprehensive Partner, Solve, Deliver approach ensures close collaboration from initial design through to full-scale global production and delivery.